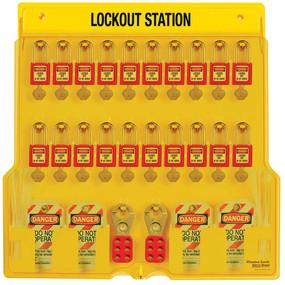

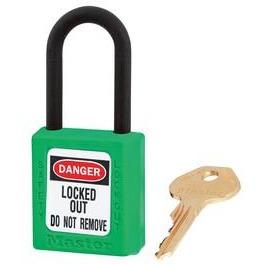

406 dielectric Zenex™ thermoplastic safety padlock

The Master Lock No. 406BLK Dielectric Thermoplastic Safety Padlock features a 38mm wide Zenex™ Thermoplastic body and a 38mm tall, 6mm diameter plastic shackle to help prevent electrocution and arc flashing and to prevent electrical current from shackle to key. All components are non-sparking and non-magnetic. Designed exclusively for Lockout/Tagout applications, the durable, lightweight material is easy to carry and the padlock has a key retaining cylinder to ensure the padlock is not left unlocked.

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Colour: | Black, Blue, Brown, Green, Orange, Purple, Red, White, Yellow |

| Key System | KD – Key Different, KA – Key Alike |

Questions about this product?

The Master Lock No. 406BLK Dielectric Thermoplastic Safety Padlock features a 38mm wide Zenex™ Thermoplastic body. And a 38mm tall, 6mm diameter plastic shackle to help prevent electrocution and arc flash. Also to prevent electrical current from shackle to key. All components are non-sparking and non-magnetic. Designed exclusively for Lockout/Tagout applications, the durable, lightweight material is easy to carry and the padlock has a key retaining cylinder to ensure the padlock is not left unlocked.

Features

- 406 dielectric thermoplastic safety padlock

- Plastic shackle helps prevent electrocution and arc flashing, also prevents electrical current from shackle to key

- All components are non-sparking and non-magnetic – plastic, copper, brass

- 38mm wide, 44mm tall, thermoplastic body, with 38mm shackle length

- Designed exclusively for lockout tagout applications

- Durable, lightweight, non-conductive thermoplastic lock body

- Compliance with “One Employee, One Lock, One Key” best practice

- Key retaining – ensures that padlock is not left unlocked

- Keyed different, 6-pin tumbler with over 40,000 available key changes cylinder

Keying options

“One Employee, One Lock, One Key”

It is important that each employee at a facility has a padlock key that is unique to them. Key charting is critical to prevent duplicate keys from entering the workplace and jeopardizing your lockout/tagout program.

A no-charge Safety Lockout Padlock Key Charting System – critical for Safety Lockout

- Key charting is a record of all the safety padlock key codes assigned to a facility

- It is important that each authorized employee at a site has a unique padlock key that only opens that employee’s safety padlock. This complies with the “one lock, one employee, one key” directive

- To help prevent duplicate keys from jeopardizing your lockout program, register your workplace with Master Lock. Once registered, Master Lock will send you an End User Identification Number for your site’s Key Chart.

- When you use that I.D. number on each additional padlock order, Master Lock will use a new key code for each padlock we manufacture for you. When used properly, this free service helps ensure that each employee caries a key unique to them, eliminating unwanted key duplication in a safety lockout program

KD – Each lock is opened by its own unique key which does not open any other lock in the set – complying with the “One lock, one employee, one key” mantra (standard delivery)

KA – All padlocks in the set are opened by the same key so only one key is necessary to open numerous padlocks – for employees who need many locks, they still only have one key

MK – A master key opens all locks within the system while each lock also has its own unique key – allows for responsible removal of improperly placed or forgotten lockouts according to your emergency notification policy (custom made to order deliver 4 to 6 weeks)

Reviews

There are no reviews yet.