Military Grade Heat-Shrink Tubing 3:1 – < 0.5 mm², White

Military grade heat shrink tubing for ultra-small wire identification. Flame-retardant 3:1 polyolefin sleeves for precise, long-lasting marking.

Key Features

| Weight | 0,6 kg |

|---|---|

| Dimensions | 15 × 15 × 10 cm |

| Shrink ratio: | 3:1 |

| Standard: | Militairy grade |

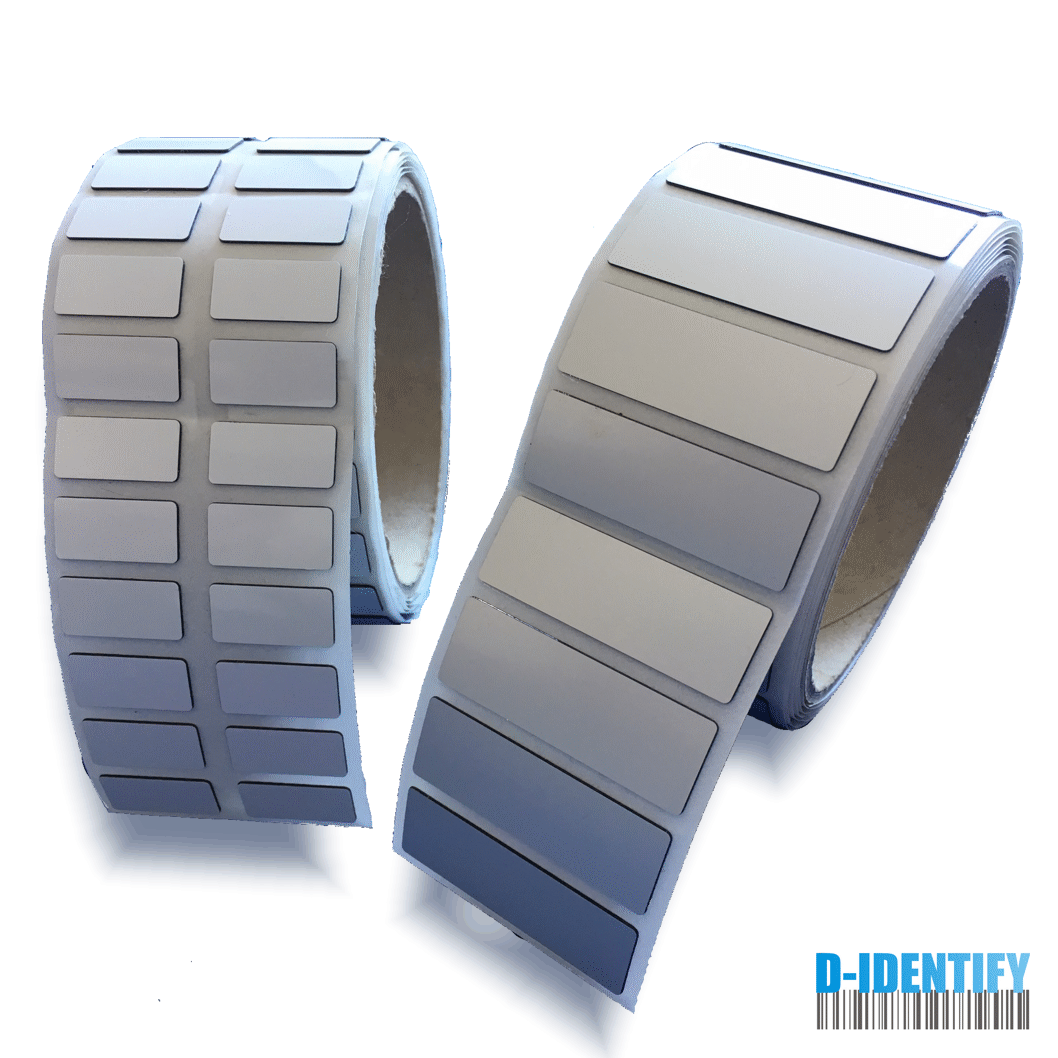

| Style: | Ladder Style Sleeves |

| Colour: | White |

| Labels/Roll: | 1000 |

| Roll core: | 76mm |

| Cable diameter: | < 0.5mm² |

€214,00 (Ex VAT)

Questions about this product?

This military grade heat shrink tubing delivers a reliable solution for identifying ultra-small wires and fine conductors in demanding technical environments. Installers select it when precision, durability, and long service life matter.

The 3:1 shrink ratio allows the tubing to fit extremely small wire diameters with accuracy. During installation, the tubing shrinks evenly and grips the conductor firmly. As a result, the marking remains secure and easy to read over time.

The tubing uses flame-retardant polyolefin. This material resists heat, abrasion, vibration, and chemical exposure. It also protects printed text from fading and smudging. Even in harsh conditions, identification stays clear.

This military grade heat shrink tubing also meets the expectations of users searching for MIL-SPEC heat shrink tubing. It prints cleanly on most 300 dpi industrial thermal transfer printers, ensuring sharp and consistent results.

Specifications

- Shrink Ratio: 3:1

- AMS-DTL-23053/5: A U.S. military specification for polyolefin heat-shrink tubing. It defines requirements for flame resistance, shrink ratio, dielectric strength, and operating temperature. Class 1 and 3 are common for cable identification.

- UL244: Flame retardant

- VW-1: A flame test rating (Vertical Wire flame test). Tubing with VW-1 approval will self-extinguish quickly if exposed to flame, reducing fire hazards.

- RoHS Compliant: Restriction of Hazardous Substances. Confirms the product is free from harmful heavy metals (lead, cadmium, mercury, etc.) and safe for use under EU environmental directives.

- SAE-AS 81531: Aerospace standard that tests the marking durability on wire and tubing. It ensures that printed text on sleeves stays legible after exposure to solvents, heat, and abrasion.

- MIL-STD-202F (Method 215J): U.S. military standard for electronic components. Method 215J specifically checks resistance of markings to solvents. It guarantees that identification does not fade or smear when cleaned with aggressive chemicals.

- Operating temperature range: -55 to 135 Celcius

- Min Recovery temperature: 85 Celcius

- Max storage temperature: 50 Celcius

- Printing mode: Single-sided or double-sided ladder type

Compatible Printers

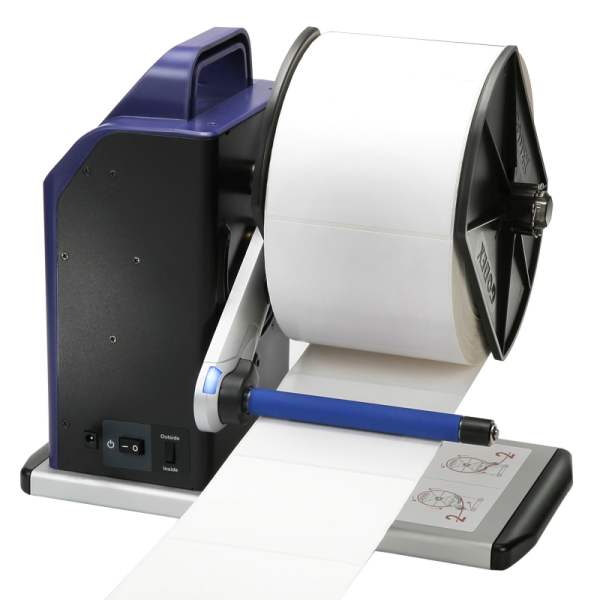

Designed for flexibility, our MIL sleeves work seamlessly with the majority of industry-standard printers. If you are unsure about compatibility, please contact us — we’ll be glad to assist.

- Tyco Raychem: T2212,T3212

- Phoenix Contact: Thermomark E300, Thermomark E300 Double, Thermomark E600 D

- Cembre: Rolly3000, ROLLY300TR2

- HellermanTyton: TT431, TT430

- Weidmüller: THM-TWINMARK, THM MULTIMARK

- Brady: I7100,i7500,BP-PR300 +,BP-PR600+

- Cab GMBH: Eos2/300,A4+ 300, A4+ 600, CAB XD Q, CAB Squix 4.3

- Altec: ATP300 Pro, ATP600 Pro, ATP3000

- Zebra: ZT510, ZT610,

- Godex:Gx4300i,Gx4600i,Zx1300Xi,RT730i,RT833i

- TSC:MH341T, TX310

- Printronix:T43X4

Reviews

There are no reviews yet.