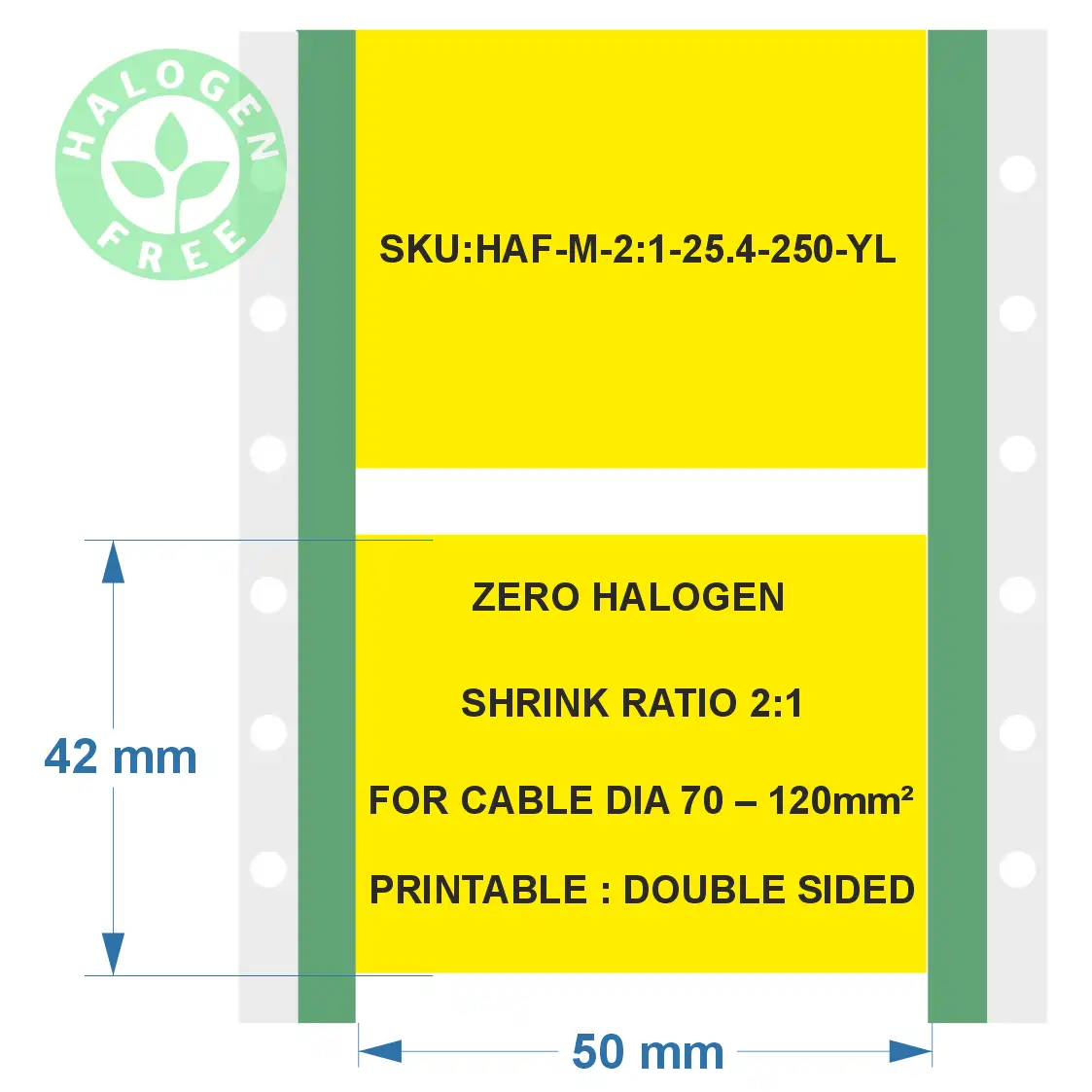

Zero Halogen Heat Shrink Tubing 2:1 – 120–185mm², Yellow

Zero halogen heat shrink tubing for professional cable identification in safety-critical environments.

Low smoke, flame-retardant sleeves with a 2:1 shrink ratio for reliable wire and cable marking.

Key Features

| Weight | 0,6 kg |

|---|---|

| Dimensions | 15 × 15 × 10 cm |

| Shrink ratio: | 2:1 |

| Standard: | Halogen Free |

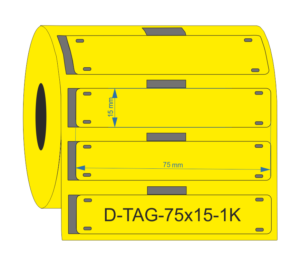

| Style: | Ladder Style Sleeves |

| Colour: | Yellow |

| Labels/Roll: | 500 |

| Roll core: | 76mm |

| Cable diameter: | 120 – 185mm² |

€403,00 (Ex VAT)

Questions about this product?

This zero halogen heat shrink tubing provides a safe and reliable solution for wire and cable identification in environments where fire safety is essential. It is widely used in rail, public transport, infrastructure projects, and industrial installations that require low smoke and halogen-free materials.

The tubing features a 2:1 shrink ratio, which allows it to fit securely over a wide range of cable sizes. After shrinking, the sleeve remains tight and stable around the cable. As a result, identification stays clear and legible over the full lifetime of the installation.

Manufactured from zero halogen polyolefin, this heat shrink tubing limits the release of toxic and corrosive gases in the event of fire. This makes it suitable for enclosed spaces and public environments where safety regulations are strict.

The material resists heat, abrasion, and common industrial chemicals. In addition, the printable surface stays clear, smudge-proof, and fade-resistant. This ensures long-term readability, even in demanding industrial conditions.

The sleeves are printable on most 300 dpi industrial thermal transfer printers, allowing users to produce clear and professional cable markers on demand. Combined with its durability and safety properties, this product offers a dependable solution for critical cable identification tasks.

Specifications

| Shrink Ratio | 2:1 |

| Fire Safety Standard (France) | NF F16-101 – French railway fire safety standard covering flammability, smoke density and toxicity. |

| Fire Safety Standard (Germany) | DIN 5510-2 – German railway standard for fire behaviour and smoke development. |

| Marking Durability Standard | SAE AS 81531 – aerospace standard verifying marking durability after exposure to solvents, heat and abrasion. |

| Solvent Resistance Test | MIL-STD-202F (Method 215J) – U.S. military test method verifying resistance of printed markings to aggressive cleaning solvents without fading or smearing. |

| Environmental Compliance | RoHS compliant – free from restricted hazardous substances such as lead, cadmium and mercury, in accordance with EU environmental directives. |

| Operating Temperature Range | −55 °C to +125 °C |

| Minimum Recovery Temperature | 115 °C |

| Maximum Storage Temperature | +40 °C |

| Printing Mode | Single-sided or double-sided, ladder type |

* Marking durability according to SAE AS 81531 can be achieved when using a compatible thermal transfer ribbon, such as TASL-R25-110×300-BK

Compatible Printers

Designed for flexibility, our MIL sleeves work seamlessly with the majority of industry-standard printers. If you are unsure about compatibility, please contact us — we’ll be glad to assist.

| Manufacturer | Compatible Printer Models |

|---|---|

| TE Connectivity (Raychem) | T2212, T3212 |

| Phoenix Contact | Thermomark E300, Thermomark E300 Double, Thermomark E600 D |

| Cembre | Rolly 3000, ROLLY300TR2 |

| HellermannTyton | TT430, TT431 |

| Weidmüller | THM-TWINMARK, THM MULTIMARK |

| Brady | i7100, i7500, BP-PR300+, BP-PR600+ |

| CAB GmbH | EOS2/300, A4+ 300, A4+ 600, CAB XD Q, CAB Squix 4.3 |

| Altec | ATP300 Pro, ATP600 Pro, ATP3000 |

| Zebra | ZT510, ZT610 |

| Godex | GX4300i, GX4600i, ZX1300Xi, RT730i, RT833i |

| TSC | MH341T, TX310 |

| Printronix | T43X4 |

Reviews

There are no reviews yet.