Military Grade Heat-Shrink Tubing 3:1 – Single Perforation, 1–4 mm²

Military grade heat shrink tubing with a single perforation for controlled handling. 3:1 polyolefin sleeves designed for smaller identifiers and clear cable marking.

Need to compare this sleeve with Brady, TE, HellermannTyton or other brands?

View the heat shrink sleeve cross reference.

Download technical datasheet (PDF)

Key Features

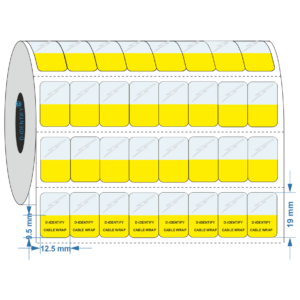

| Shrink ratio: | 3:1 |

|---|---|

| Standard: | Militairy grade |

| Style: | Ladder style with perforation |

| Colour: | White |

| Roll core: | 76mm |

| Labels/Roll: | 2000 |

| Cable diameter: | 1 – 4mm² |

€301,00 (Ex VAT)

Questions about this product?

This military grade heat shrink tubing offers a durable solution for wire and cable identification in demanding environments. Installers use it when they need long-lasting markings and consistent results.

The sleeve features a 3:1 shrink ratio, which allows it to fit a wide range of cable diameters. During installation, the tubing shrinks evenly and grips the conductor firmly. The marking stays secure and easy to read over time.

This version includes one perforation per sleeve. That design supports longer identifiers or more detailed text, while still allowing clean separation by hand. The sleeve keeps its full printable length.

The tubing uses flame-retardant polyolefin. The material resists heat, abrasion, vibration, and chemicals. It also protects printed text against fading and smudging, even in harsh conditions.

This military grade heat shrink tubing prints cleanly on most 300 dpi industrial thermal transfer printers. Professionals rely on it as MIL-SPEC heat shrink tubing for critical cable identification tasks.

Specification

| Shrink Ratio | 3:1 |

| Material Standard | AMS-DTL-23053/5 – U.S. military specification for polyolefin heat-shrink tubing. Defines requirements for flame resistance, shrink ratio, dielectric strength and operating temperature. Class 1 and Class 3 are commonly used for cable identification. |

| Flame Retardancy | UL 224 compliant |

| Flame Test Rating | VW-1 (Vertical Wire flame test). Tubing self-extinguishes quickly when exposed to flame, reducing fire hazards. |

| Environmental Compliance | RoHS compliant – free from restricted hazardous substances such as lead, cadmium and mercury, in accordance with EU environmental directives. |

| Marking Durability Standard | SAE AS 81531 – aerospace standard verifying marking durability after exposure to solvents, heat and abrasion. |

| Solvent Resistance Test | MIL-STD-202F (Method 215J) – confirms resistance of markings to aggressive cleaning solvents without fading or smearing. |

| Operating Temperature Range | −55 °C to +135 °C |

| Minimum Recovery Temperature | 85 °C |

| Maximum Storage Temperature | 50 °C |

| Printing Mode | Single-sided or double-sided, ladder type |

* Marking durability according to SAE AS 81531 can be achieved when using a compatible thermal transfer ribbon, such as TASL-R25-110×300-BK

Compatible Printers

Designed for flexibility, our MIL sleeves work seamlessly with the majority of industry-standard printers. If you are unsure about compatibility, please contact us — we’ll be glad to assist.

| Manufacturer | Compatible Printer Models |

|---|---|

| TE Connectivity (Raychem) | T2212, T3212 |

| Phoenix Contact | Thermomark E300, Thermomark E300 Double, Thermomark E600 D |

| Cembre | Rolly 3000, ROLLY300TR2 |

| HellermannTyton | TT430, TT431 |

| Weidmüller | THM-TWINMARK, THM MULTIMARK |

| Brady | i7100, i7500, BP-PR300+, BP-PR600+ |

| CAB GmbH | EOS2/300, A4+ 300, A4+ 600, CAB XD Q, CAB Squix 4.3 |

| Altec | ATP300 Pro, ATP600 Pro, ATP3000 |

| Zebra | ZT510, ZT610 |

| Godex | GX4300i, GX4600i, ZX1300Xi, RT730i, RT833i |

| TSC | MH341T, TX310 |

| Printronix | T43X4 |

Reviews

There are no reviews yet.